-

-

SMT -

Robotics -

About Us -

Contact Us

Events

News-

Sales Network

YSM10 Surface Mount Technology | Compact Mounter

Ultimate basic machine featuring the three "1"

1 head solution!

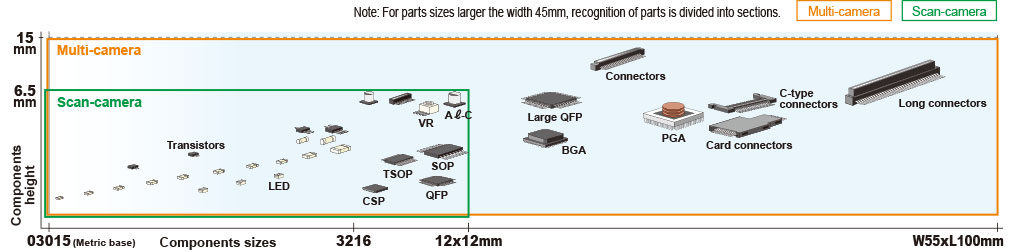

Handles a wide range of components from 03015mm (0.3 × 0.15mm) ultra-micro-chips to large parts 55 × 100mm and 15mm in height and needs no head replacement since it uses high-speed general-purpose heads the same as high-end models.

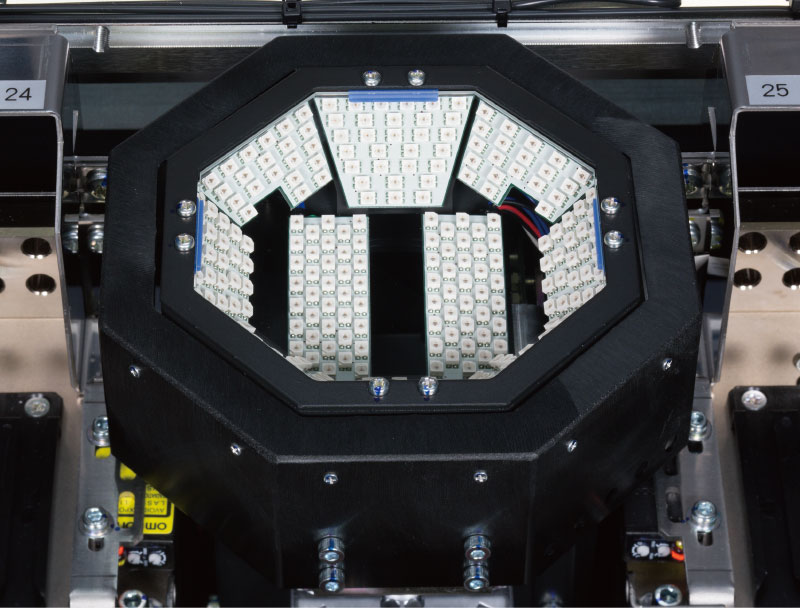

New Scan Camera

Improves scan camera performance that expands the size of high-speed mounting parts to 12mm.Supports ball recognition such for BGA and CSP, etc.

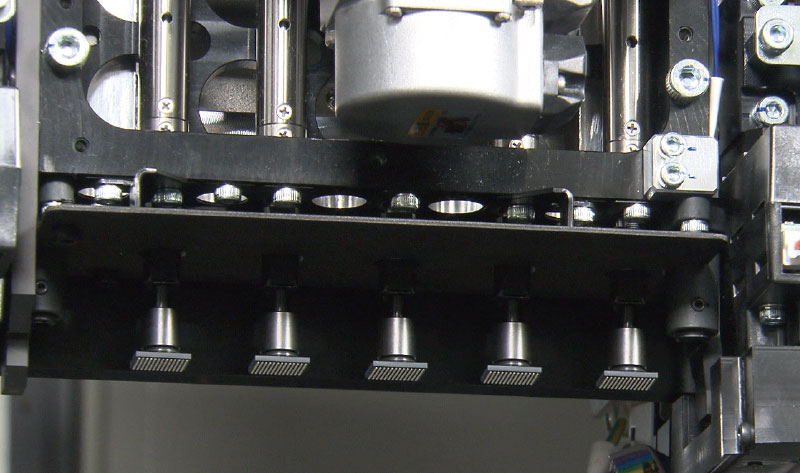

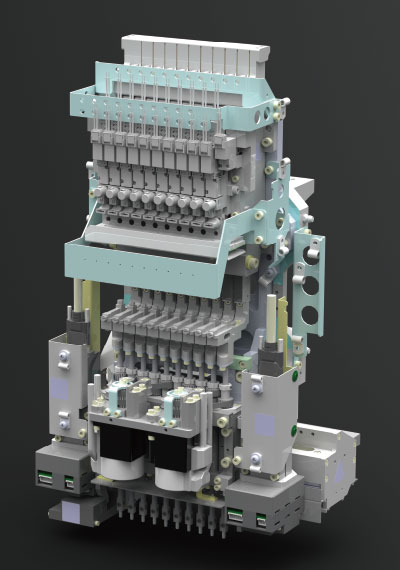

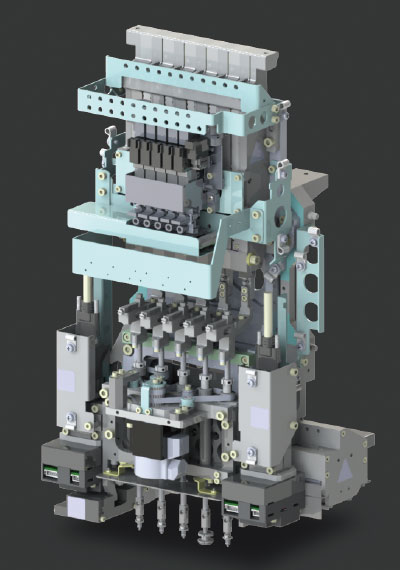

HM (High-speed Multi) head

Standard type with 10 nozzle specifications for a compact body, light-weight, high-speed and versatility.

HM 5 head

Economy type having 5 nozzles with HM head functions unchanged, it is selectable according to productivity and budget needs.

The world’s fastest mounting speed in its class!

By adopting a new-generation servo system from upper-ranked models and utilizing a lightweight and compact universal type head we have speeded up mounting more than 25% compared to conventional models to achieve the world’s fastest mounting speed in its class of 46,000 CPH (chips per hour).

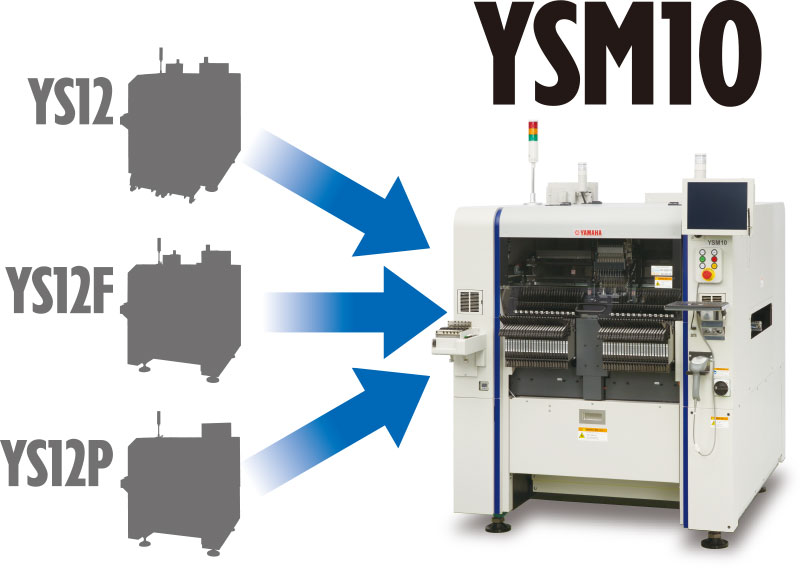

Single Platform

Here, 3 models or namely the YS12 with flexibility and mobility, YS12P with some simpler specifications, and YS12F with superb component handling compatibility are integrated into one type of platform. This is a super-entry model combining high parts compatibility and versatility along with the usual small size body, high speed, and space saving specs.

Flexible response for different production configurations!

Compatible components

Multi-Camera

High-speed and high-accuracy parts recognition to sizes exceeding 12mm or heights exceeding 6.5mm.

Nozzle Station

Automatic replacement of spare nozzles and special order nozzles available.

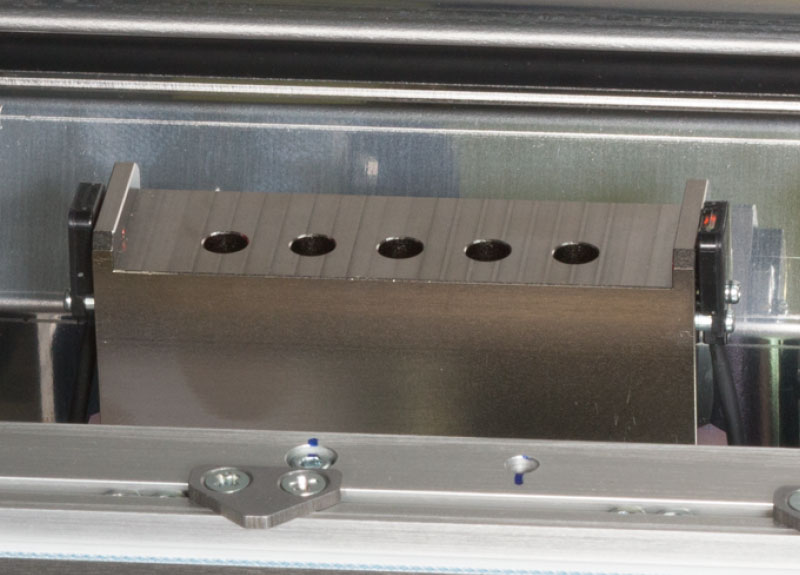

Automatic replacement tray supply unit "sATS15"

A maximum of 15 parts trays can be loaded. (at tray pitch of 12.5mm)

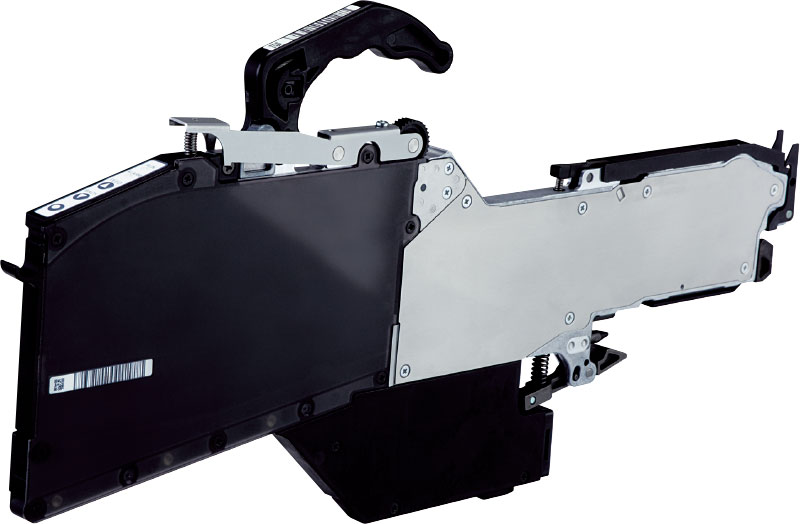

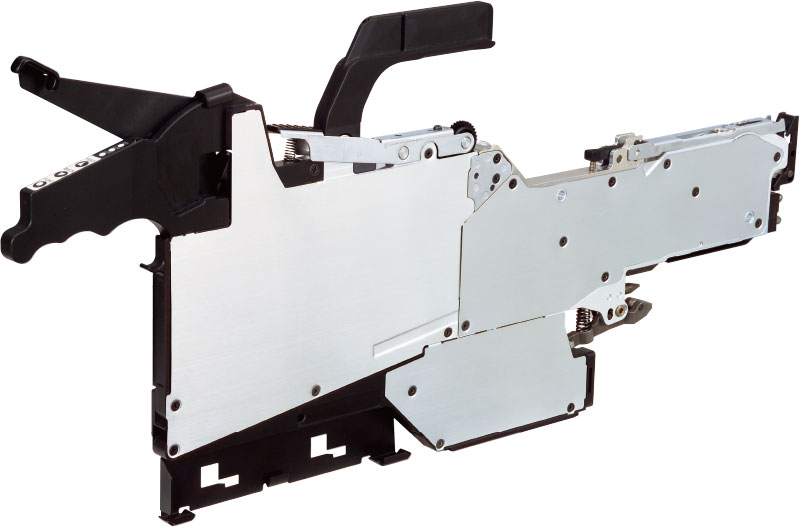

Tape feeder

Electric-drive intelligent feeders "SS feeder" and "ZS feeder" fully compatible with all YS series models.

Functions that ensure stable production

Side view function

Eliminates mounting errors by detecting parts, missing parts, and part pickup status with no time loss.

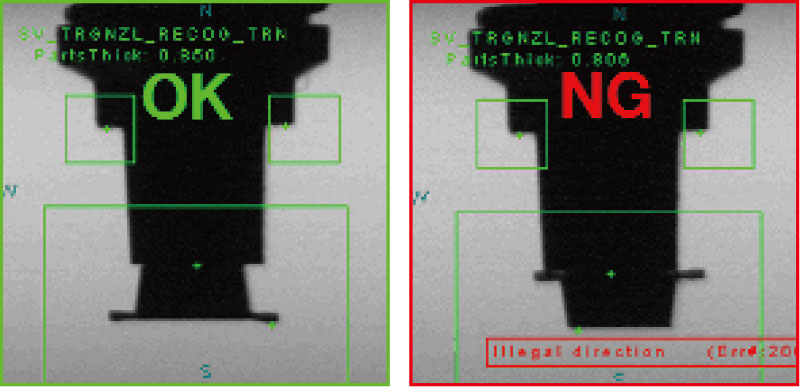

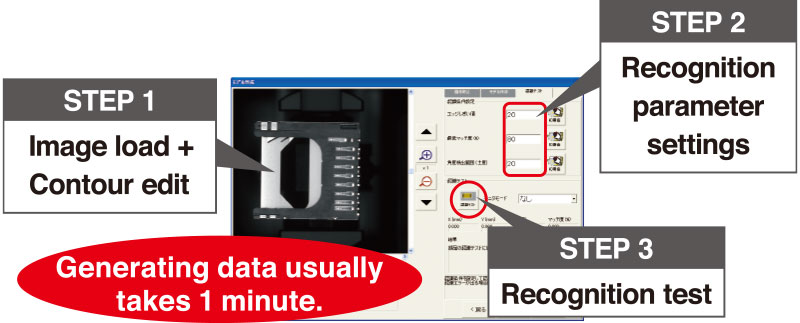

Automatic recognition optimizer function

Prevents pickup and recognition errors by applying a function (smart recognition) that does easy data generation for parts having complex shapes and also a recognition data auto-generator & tracking function. (es-Vision)

Blow Station

Nozzle shafts are automatically cleaned to keep the nozzle in good condition for long periods of time. A nozzle health check function applies automatic recovery processes such as nozzle blow and a protect function to prevent use of abnormal nozzles.

Highly stable & reliable pickup system

Maintains superb part pickup performance by way of a pickup height auto--teach function and pickup position auto compensator function.

Conforms to CE marking standards

Worldwide operability with equipment design that gives safety number one priority.

Note: This name signifies a safety standard required for equipment for install and usage in Europe.