-

-

SMT -

Robotics -

About Us -

Contact Us

Events

News-

Sales Network

Module LCM-X Industrial Robots | Linear Conveyor

+/- 5μm

Repeatability

Up to 64

Sliders

Compact

Linear Motor

Low 85mm

Profile

Features

01 Centralized control with the Universal Controller

A single Universal Controller can control all the sliders in a centralized manner including slider circulation.

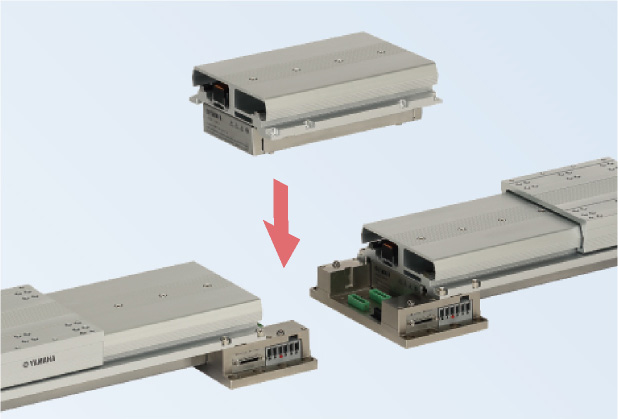

02 The bridge pier structure enables speedy setup.

Installation work, including coupling of each module, can be completed in a very easily in a short time using the connection unit that enables quick mechanical high-precision positioning and electrical connection of each model.

03 Top cover incorporated

A cover to protect the guide rail, motor, and sensors is attached to the top face to prevent faults caused by falling objects in each work process.

04 All the sliders can be operated / programmed independently.

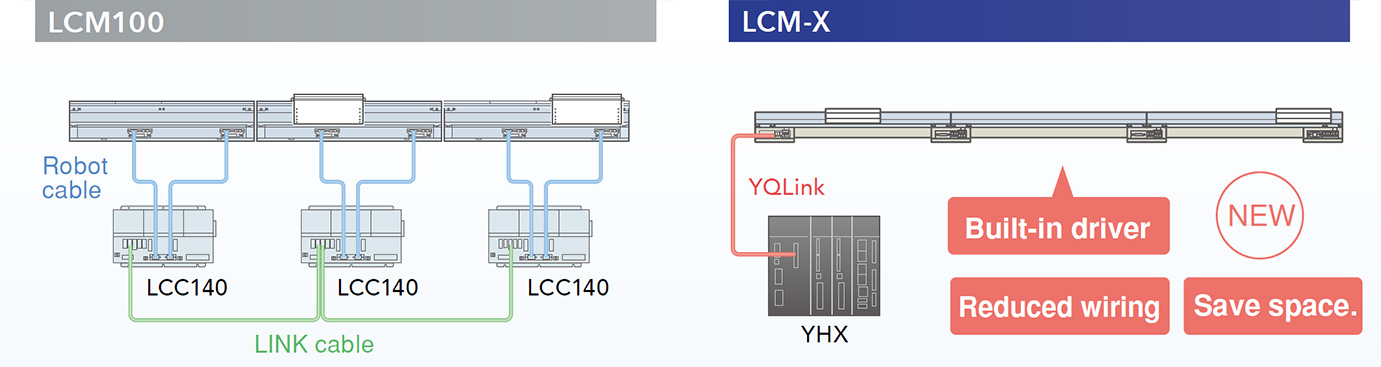

05 Use of the motor driver integrated into and put together with the main body saves electrical wiring.

The unitized electro-mechanical structure with a motor driver built in the module controls entire LCM-X. Connecting with the Universal Controller via one YQ Link cable is all you have to do. It surely contributes to saving space in the control panel.

06 Recognize slider’s individual IDs

The multi-track magnetic sensor enables to identify a slider ID at any point in the transport process. Even if you have unintentionally changed sliders, the system correctly identifies the ID of each slider.

07 Mechanical tolerance between sliders +/-10 µm

When stopping two or more sliders at a point one after another, the actual stop positions are inevitably different because each slider has its own error width (machine difference). The LCM-X minimizes the width error among the sliders within as little as ±10µm to best suit high accuracy processes. Costs can be reduced as there is no need for RFID, etc.

08 No origin process needed

Newly developed high-precision full-range absolute server eliminates the need for return-to-origin. The operation can be started and stopped easily, so there is no time loss even when starting or restarting.

09 High acceleration rate

High speed motion between an extremely short distance is possible even in a high density process or pitch feed.

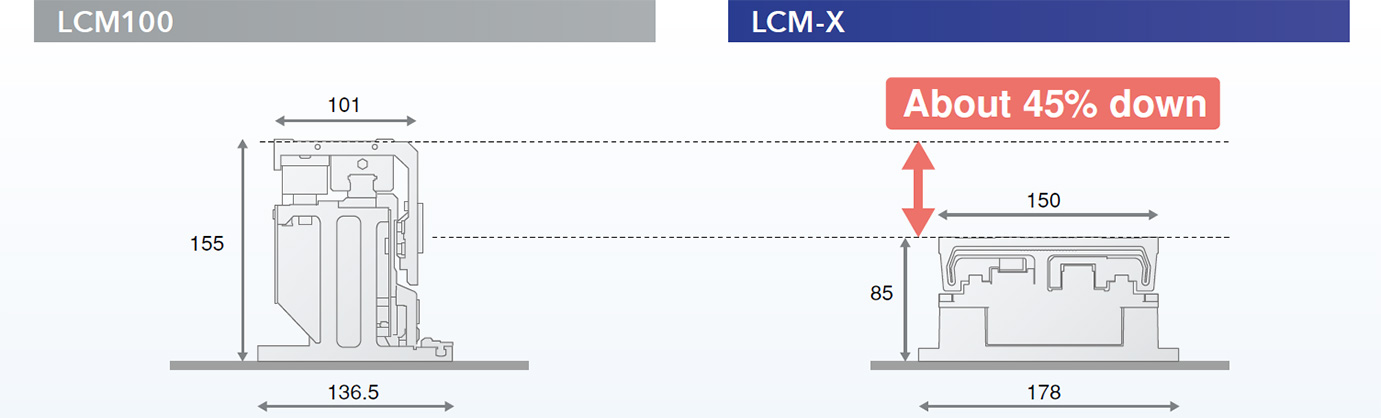

10 Low profile structure

Use of the newly developed linear motor makes the module height approximately half compared with the previous model. You can also use a space under the frame.

Specifications

Clicking a desired model name allows you to see its detailed catalog.

| Model | LCM-X | |

|---|---|---|

| Drive method | Linear motor with moving magnet type core | |

| Position Search | Full range absolute position detection sensor and full range slider ID detection | |

| Maximum payload | 15 kg | |

| Maximum speed | 3,000 mm/sec *1 | |

| Repeatability | +/- 5μm | |

| Mechanical tolerance between robot sliders | +/- 10μm | |

| Total stroke limit | Approx. 25 m *2 | |

| Maximum number of robot sliders | 64 units *2 | |

| Minimum spacing between robot sliders | 210mm | |

| Main frame dimensions | Max. external size of frame cross-section | W178 × H85 mm (Including robot slider) |

| Linear module length | 200mm / 300mm / 500mm / 1000mm | |

| Robot slider length | 198mm | |

| Weight | Linear module | 10 kg [Per 1 m of linear module] |

| Robot slider | 1.2kg | |

| Connection unit | 0.6kg | |

| Power supply | Control power supply | 48 VDC +5%, -10%, 75 W [Per 1 m of linear module] |

| Motor power supply *3 | 48 VDC +/-10%, 1000 W at maximum (at max. acceleration) | |

| Maximum current capacity *4 | Total30A [Control power supply: 15Amax., Motor power supply: 30Amax] | |

| Operating environment | Operating temperature | 0℃ - 40℃ *6 |

| Storage temperature | -10℃ - 65℃ | |

| Operating humidity | 35% - 85%RH [No condensation] | |

| Controller | YHX series *5 | |

*1 2m/sec when the payload is 10 kg or more.

*2 It may differ depending on the system configuration.

*3 Different from one motion pattern to another.

*4 Maximum current capacity for one input section (one connection unit). Where the electrical power

demand exceeds the input capacity, supply electrical power through multiple input sections.

*5 The YHX controller requires a separate electrical power supply.

*6 Operate LCM-X in the temperature environment (±5 °C) that installation and adjustment were performed.